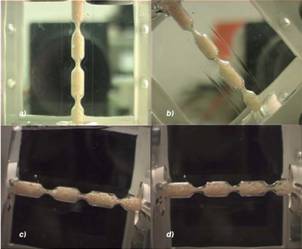

Solid Suspension using OFM: Experiments involving the suspension of solid particles with OFM have shown the possibility of achieving better homogeneity of solids suspension in a tube operated with OFM. Figures 1-3 show the suspension of ion-exchange resin particles in a small-scale oscillatory flow reactor, 5 mm i.d.

|

|

Figure 1. Complete suspension of 40 % v/v of ion exchange resin particles at varying angles and similar oscillation conditions: (a) vertical position, f = 12.1 Hz, x0 = 4 mm; (b) 45 degrees, f = 12.1 Hz, x0 = 4 mm; (c) 10 degrees, f = 12.1 Hz, x0 = 3 mm; (d) horizontal position, f = 12.1 Hz, x0 = 3 mm. In b), c) and d), the right hand side corresponds to the bottom of the reactor. |

|

|

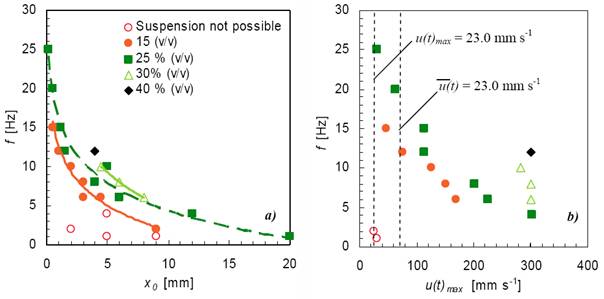

Figure 2. a) maximum concentration of ion exchange resin particles completely suspended at different fluid oscillations frequencies and amplitudes in the vertical position; b) minimum u(t)max (maximum oscillation velocities) for complete suspension of particles, at different fluid oscillation frequencies. |

|

|

Figure 3. Suspension of catalyst particles in the vertical position: instantaneous velocity vector maps of fluid phase at Reo = 625, xo = 2 mm, f = 10 Hz in the presence of 3% (v/v) amount of ion-exchange particles. |