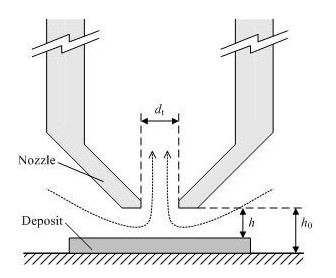

Fluid dynamic gauging is a technique whereby the surface of the deposit is exposed to a fluid jet sucking into a nozzle located close to that surface. The suction/gauging flows into the nozzle are maintained by a fixed hydrostatic head, simply maintained by a siphon tube. Measurement of the flowrate, m, yields the clearance between the nozzle tip and the deposit surface, h. By knowing the distance from the nozzle to a clean substrate, ho, the thickness of the layer, δ, can be determined from δ = h - ho, as can any change in thickness resulting from deposition (or growth), or cleaning. The instrument is simple in principle and cheap to construct: its exploitation lies in coupling accurate measurements with device design and, more recently, flow simulations and imaging technologies. Typical layers studied to date include whey protein gels, egg albumin, cooked tomato paste [a model food fouling layer] and latex polymers, with thicknesses ranging from 40 μm to 2 mm, at a precision of ±5 μm using the most recent designs.

Fluid dynamic gauging is a technique whereby the surface of the deposit is exposed to a fluid jet sucking into a nozzle located close to that surface. The suction/gauging flows into the nozzle are maintained by a fixed hydrostatic head, simply maintained by a siphon tube. Measurement of the flowrate, m, yields the clearance between the nozzle tip and the deposit surface, h. By knowing the distance from the nozzle to a clean substrate, ho, the thickness of the layer, δ, can be determined from δ = h - ho, as can any change in thickness resulting from deposition (or growth), or cleaning. The instrument is simple in principle and cheap to construct: its exploitation lies in coupling accurate measurements with device design and, more recently, flow simulations and imaging technologies. Typical layers studied to date include whey protein gels, egg albumin, cooked tomato paste [a model food fouling layer] and latex polymers, with thicknesses ranging from 40 μm to 2 mm, at a precision of ±5 μm using the most recent designs.

Some of the interesting features of this novel gauging technique are:

- The thickness of the deposit is determined simply by measuring the discharge flow rate of the liquid obtained from the free end of the siphon tube.

- It is easy to install and operate.

- By use of a siphon, the processing fluid is sucked out of the apparatus, hence avoiding the introduction of foreign matter into the system (that might compromise its sterility, for example).

- The gauge can also be used as a sampling device where the discharge fluid from the apparatus can be analysed.

- The physical properties of the deposit rarely need to be taken in consideration.

- It does not require sophisticated equipment and can be built cheaply.

- The gauge can also readily accommodate non-Newtonian and flammable fluids.

Two configurations of FDG are currently in use, namely the quasi-stagnant and the duct-flow. In the quasi-stagnant system, the main components are the gauging nozzle, siphon tube and a tank containing the process fluid. The only substantial fluid movement is the gauging flow. For duct-flow, the gauging process is performed in a duct, simulating FDG in a pipe flow.