|

Melt processing and foaming of starch |

Introduction

The main objective of Nitin's project was to study the melt processing and foaming of starch using the Cambridge Multi Pass Rheometer (MPR) to better advance the undertstanding of the rheological and foaming behaviour of starch melts. The rheological properties were studied using the MPR with a middle-test section fitted with a capillary, while a quartz-window arrangement was used to investigate in situ bubble nucleation and foaming within starch melts.

In outline, starch powder is converted into a melt, which is then moved to and fro by the two pistons of the MPR, synchronously driven over a range of constant velocities. These experiments yielded shear data that characterised the rheological behaviour of molten starch. Foaming, on the other hand, was achieved by decompressing the melt so that the dissolved blowing agent flashed and generated bubbles. In situ bubble nucleation and growth was thus be studied at different operating conditions of the MPR for different types of starch samples.

Starch

Starch is the cheapest and most abundant food biopolymer worldwide. It occurs in a variety of botanical sources including potato, wheat and maize and has found diverse applications ranging from breakfast cereals, snacks and thickeners in the food industry to binders for drug delivery systems, packaging, paper and adhesives in the non-food industry.

For certain applications in the food and packaging industries, starch is extruded to achieve a desired product texture and quality. Some work has already been carried out and published on extrusion and extrusion expansion in general. However, there are many more challenges in the study of starch processing as a result of the compositional, structural and rheological complexities of starch systems, as well as inhomogenieties encountered during processing.

An understanding of the mechanisms involved in the processing and expansion of starch is therefore required. Such insight would help optimise existing extrusion processes through better equipment design and applications, and develop new products with desired characteristics that would benefit both the consumers and the industry.

Composition and Structure

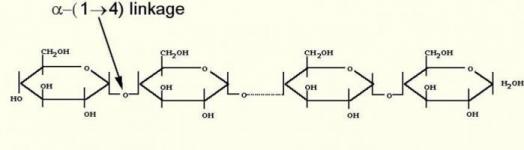

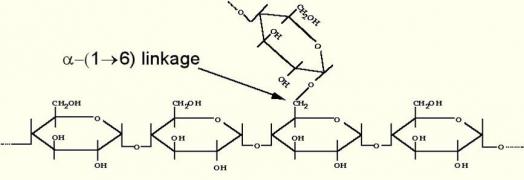

Starch is produced as granules in most plants cells and is referred to as "native" when in this particular granular state. Native starches from different botanical sources vary widely in structure and composition, but all granules consist of two major molecular components, amylose (20-30%) and amylopectin (70-80%), both of which are polymers of α-D-glucose units in the 4C1 conformation. In amylose (Figure 1), these are linked -(1 → 4)-, with the ring oxygen atoms all on the same side, whereas in amylopectin about one residue in every twenty is also linked -(1 → 6)- forming branch-points as shown in Figure 2.

|

| Figure 1 - Amylose molecule |

|

| Figure 2 - Amylopectin molecule |

Several investigations have been carried out to establish the level of organization within the starch granules. Techniques used vary from X-ray diffraction experiments to atomic force microscopy (AFM) and transmission electron microscopy (TEM). In the native form of starch, amylose and amylopectin molecules are organised in granules as alternating semi-crystalline and amorphous layers that form growth rings as illustrated in Figure 3. The semi-crystalline layer consists of ordered regions composed of double helices formed by short amylopectin branches, most of which are further ordered into crystalline structures known as the crystalline lamellae. The amorphous regions of the semi-crystalline layers and the amorphous layers are composed of amylose and non-ordered amylopectin branches.

|

| Figure 3 - Schematic view of the structure of a starch granule, with alternating amorphous and semi-crystalline zones constituting the growth rings. |

Extrusion of Starch

Extrusion is a forming technique whereby a material is forced, by compression, through a shaped opening in a die to produce a continuous profile. The material can be ram- or (single- or twin-screw) screw-extruded. The latter technique is more widely used in converting raw polymer, usually in powder or pellet form, through a combination of mixing, shearing, shaping and forming processes into a saleable finished or semi-finished product, with a particular shape and/or texture only achievable via extrusion routes. The combined effect of shear, temperature and local shear-induced temperature changes inside the extruder screw channel make the thermomechanical process during screw extrusion unique. Such a process is used with relatively dry materials to plasticize food mass, reduce microbial load, denature enzymes, gelatinize starch, polymerize proteins and, most importantly, texturize the end product into a desirable form. Screw extrusion has proved to be a particularly very attractive process in the food industry, with the advantages of versatility, high productivity, low cost, energy efficiency and no effluents causing waste problems.

Extrusion expansion is a complex phenomenon which occurs during high-temperature, low-moisture cooking and is a consequence of several events including starch structural transformations and phase transitions, nucleation, extrudate swell, bubble growth, and bubble collapse, with bubble dynamics dominantly contributing to the expansion phenomenon as shown in Figure 4.

|

| Figure 4 - Schematic diagram of extrudate expansion |

The main factors that significantly influence extrusion expansion are summarized in Figure 5.

|

| Figure 5 - Factors influencing extrudate expansion |

Nucleation and Foaming

The gas cell structure of expanded starchy extrudates is directly related to the number of bubbles nucleated within the starch melt. Understanding the formation of the cellular matrix at the end of the expanded extrusion process requires a good understanding of the nucleation phenomenon which is responsible for the formation of individual bubbles. Nucleation and growth affect the cell size distribution in synthetic polymer foaming, with nucleation having the strongest effect. Nucleation within food biopolymers is complex process principally because of the intrinsic complexity of the behaviour of biopolymers that undergo continuous transformations during extrusion. This is why most of the nucleation models, brought forward to this date, are based on simplifying assumptions for developing quantitative predictions of nucleation rates in extrusion of biopolymeric melts.

At saturation conditions, the pressure in the liquid and vapour in the immediate vicinity of the gas bubble (Figure 6) are such that the force equilibrium established at the interface of the spherical gas bubble in a liquid medium can be expressed by the Laplace equation:

ΔP = (PG - PL) = 2σR-1

where PG is the pressure of the vapour phase inside the gas bubble, PL is the pressure of the surrounding liquid phase, σ is the surface tension of the polymer melt-gas interface and R is the radius of the spherical bubble.

|

| Figure 6 - Spherical gas bubble in polymer melt containing dissolved gas |

Nucleation consists of the formation of small, thermodynamically unstable, gaseous embryos within the liquid metastable phase. Once an embryo reaches a critical size, Rcrit, it grows spontaneously into a stable and permanent bubble, called nucleus. As superheating increases, ΔP becomes larger due to the increase in PG, making the nucleus radius, R smaller. High degrees of superheating could even make the size of the nuclei comparable to molecular dimensions. Embryos usually form as a result of either homogeneous or heterogeneous nucleation. Homogeneous nucleation is caused by localized thermal and density fluctuations of a metastable liquid phase. There are no gas cavities present prior to the system being superheated or made supersaturated. The degree of superheating required is therefore relatively high and once molecule clusters with vapour-like energies form, these further develop into critical vapour embryos. When the system is made superheated or supersaturated by a sudden pressure reduction for example, embryos may also form in a pit in the surface of the container and on suspended non-wetted solids. These bubbles further grow and detach, leaving behind a portion of the gas making up the density fluctuation within the liquid phase. The production of these first bubbles is referred to as heterogeneous nucleation.

Starchy extrudate expansion is governed by the biaxial extension of individual bubbles and the driving force for bubble growth is the pressure difference, ΔP between the inside and the exterior of the biopolymer matrix. The rheological properties of molten polymer matrix have a leading role over surface tension in expansion, since they determine the resistance of the bubble wall to ΔP. The study of bubble growth within synthetic polymer melts is significantly covered in the literature and the associated modelling is mainly based on three governing equations for single bubble growth relating to the overall force balance on the melt, mass balance of the gas in the polymer melt and the mass balance on the bubbles.

References

Starch structure

Bulon, A., Colonna, P., Planchot, V., Ball, S., 1998, Starch granules: structure and biosynthesis, International Journal of Biological Macromolecules, 23, 85-112

Gallant, D.J., Bouchet, B., Baldwin, P.M., 1997, Microscopy of starch: evidence of a new level of granule organization, Carbohydrate Polymers, 32, 177-191

Jenkins, P.J., Donald, A.M., 1995, The influence of amylose on starch granule structure, International Journal of Biological Macromolecules, 17, 315-321

Jobling, S., 2004, Improving starch for food and industrial applications, Current opinion in Plant Biology, 7, 1-9

Oates, C.G., 1997, Towards an understanding of starch granule structure and hydrolysis, Trends in Food Science & Technology, 8, 375-382

Parker, R., Ring, S.G., 2001, Aspects of the physical chemistry of starch, Journal of Cereal Science, 34, 1-17

Ridout, M.J., Gunning, A.P., Parker, M.L., Wilson, R.H., Morris, V.J., 2002, Using AFM to image the internal structure of starch granules, Carbohydrate Polymers, 50, 123-132

Singh, N., Singh, J., Kaur, L., Sodhi, N.S., Gill, B.S., 2003, Morphological, thermal and rheological properties of starches from different botanical sources, Food Chemistry, 81, 219-231

Waigh, T.A, Hopkinson, I., Donald, A.M., 1997, Analysis of the native structure of starch granules with X-ray microfocus diffraction, Macromolecules, 30, 3813-3820

Extrusion

Alvarez-Martinez, L., Kondury, K.P., Harper, J.M., 1988, A general model for the expansion of extruded products, Journal of Food Science, 53, 609-615

Bhattacharya, M., Hanna, M.A., 1988, Effects of lipids on the properties of extruded products, Journal of Food Science, 53 (4), 1230-1231

Chuang, G.C., Yeh, A., 2004, Effect of screw profile on residence time distribution and starch gelatinization of rice flour during single screw extrusion cooking, Journal of Food Engineering, 63, 21-31

Glenn, G.M., Orts, W.J., 2001, Properties of starch-based foam formed by compression-explosion processing, Industrial Crops and Products, 13, 135-143

Kokini, J.L., 1993, The effect of processing history on chemical changes in single- and twin screw extruders, Trends in Food Science & Technology, 4, 324-329

Moraru, C.I., Kokini, J.L., 2003, Nucleation and expansion during extrusion and microwave heating of cereal foods, Comprehensive reviews in Food Science and Food Safety, 2, 120-138

Stevens, M.J., Covas, J.A., 1995, Practical Extrusion Processes and their Applications. In: Stevens, M.J., Covas, J.A. (editors), Extruder Principles and Operations, Chapman & Hall, 2nd edition, pp 4-26

Nucleation and Foaming

Alavi, S.H., Rizvi, S.S.H., Harriott, P., 2003a, Process dynamics of starch-based microcellular foams produced by supercritical fluid extrusion. I: Model development, Food Research International, 36, 309-319

Alavi, S.H., Rizvi, S.S.H., Harriott, P., 2003b, Process dynamics of starch-based microcellular foams produced by supercritical fluid extrusion. II: Numerical simulation and experimental evaluation, Food Research International, 36, 321-330

Delale, C.F., Hruby, J., Marsik, F., 2003, The classical theory of homogeneous bubble nucleation revisited, 5th International Symposium on Cavitation, Osaka, Japan, November 1-4, 2003, Paper No: Cav03-GS-1-002

den Doelder, C.F.J., Sammler, R.L., Koopmans, R.J., Paquet, A.N., 2002, Modelling foam growth in semi-crystalline thermoplastics, Cellular Polymers, 21 (2), 99-116

Jones, S.F., Evans, G.M., Galvin, K.P., 1999, Bubble nucleation from gas cavities: a review, Advances in Colloid and Interface Science, 80, 27-50

Kokini, J.L., Chang, C.N., Lai, L.S., 1992, The role of rheological properties of extrudate expansion, In: Kokini, J.L, Ho, C.T., Karwe, M.V. (editors), Food extrusion science and technology, New York, N.Y., Marcel Dekker Inc, pp 631-653

Koopmans, R.J., den Doelder, J.C.F., Paquet, A.N., 2000, Modelling foam growth in thermoplastics, Advanced Materials, 12 (23), 1873-1879

Pai, V., Favelukis, M., 2002, Dynamics of spherical bubble growth, Journal of Cellular Plastics, 38, 403-417

Shafi, M.A., Joshi, K., Flumerfelt, R.W., 1997, Bubble size distributions in freely expanded polymer foam, Chemical Engineering Science, 52 (4), 635-644

Shafi, M.A., Flumerfelt, R.W., 1997, Initial bubble growth in polymer foam processes, Chemical Engineering Science, 52 (4), 627-633

Shen, V.K., Debenedetti, P.G., 2003, A kinetic theory of homogeneous bubble nucleation, Journal of Chemical Physics, 118 (2), 768-783

Return to the main Alumni page