Submitted by Ellie Hall on Tue, 06/12/2022 - 15:22

Researchers at the University of Cambridge have developed a system of artificial leaves that use sunlight to turn carbon dioxide and water into a synthetic fuel known as syngas. Their scaled-up demonstrator system, built for the final of the European Union’s ‘Fuel from the Sun’ competition, showed potential for the production of syngas under real-world conditions.

The demonstrator project was the culmination of 3 years of development by research groups from the Yusuf Hamied Department of Chemistry and the Department of Chemical Engineering and Biotechnology at the University of Cambridge, to compete for the EU Fuel from the Sun Prize, which offers a €5M award.

The challenge was to build a fully functional, bench-scale prototype of an artificial photosynthesis-based system which can produce a useable synthetic fuel. Results of the competition were announced at the award ceremony today in Brussels.

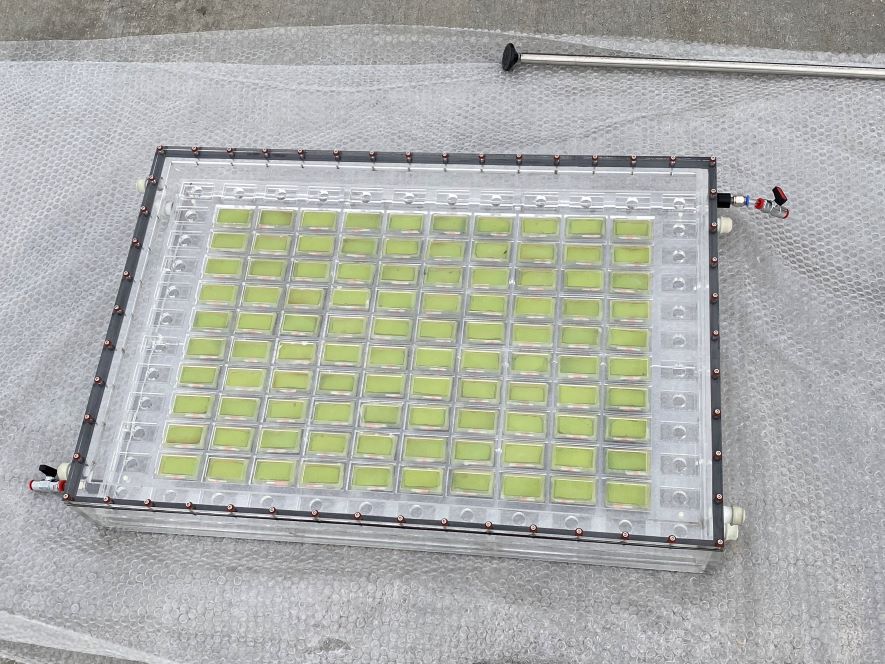

The team’s concept was to make a large array of artificial leaves using a combination of halide perovskite light absorbers – as a state-of-the art alternative to silicon solar panels – and photo-catalysts. The ‘leaves’ use artificial photosynthesis to convert sunlight, carbon dioxide and water into synthetic gas or ‘syngas’ which can in turn be converted into liquid fuels such as hydrocarbons or alcohols.

Syngas produced in this way could eventually replace the gases currently sourced from traditional fossil fuels and meet the major demand from areas such as transport and shipping for sustainable, clean fuel.

The project combines previous research on artificial leaves from Professor Erwin Reisner’s group at the Yusuf Hamied Department of Chemistry in Cambridge with a new approach to halide perovskite processing developed in Professor Sam Stranks’s group at the Department of Chemical Engineering and Biotechnology.

Scaling up for the competition

While artificial leaves are not a new concept, existing prototypes have been difficult to deploy outside a laboratory environment and have mainly produced only hydrogen. The researchers’ previous work demonstrated the structures on a small scale, and the big challenge for the competition was scale-up.

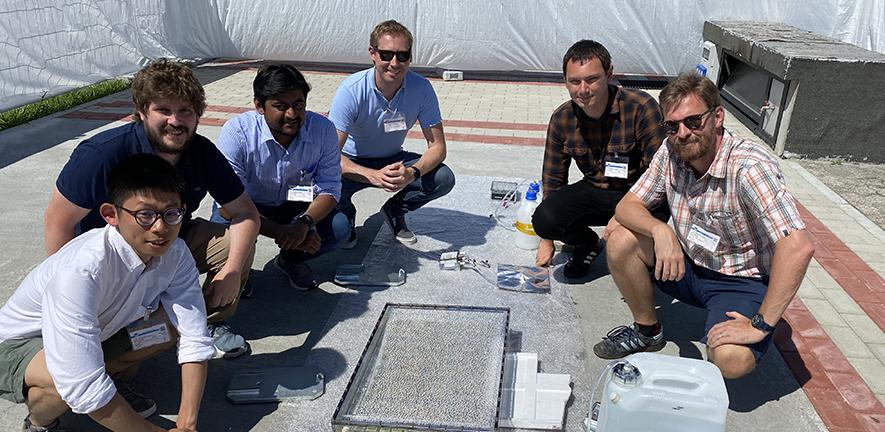

The scaled up system was built at the Maxwell Centre in Cambridge, which hosted the team during the months leading up to the competition Using the Henry Royce Institute Ambient Cluster Tool, the team was able to scale up their production of halide perovskite solar cells in a process called thermal evaporation. This enabled them to produce larger artificial leaf panels that could be combined to build a completely scalable, modular system. The system assembly happened in the Maxwell’s Cambridge Zero Demonstrator Lab, and the panels were given their first outdoor test runs on the compound rooftop at the rear of the building.

“This has been an extremely exciting yet challenging project," said Professor Stranks, "ranging from fundamental materials science, chemistry and physics, to scaled-up engineering of the photo-absorbers and catalysts, utilising a range of different experimental deposition and characterisation tools.”

Professor Manish Chhowalla, Royce Research Area Lead the University of Cambridge, said: “Congratulations to all involved in this very timely, ground-breaking project. It’s fantastic to see Royce capability being utilised to advance the development of sustainable fuel. On behalf of Royce, we wish the project team every success on the next steps of their innovation journey.”

What the future holds

While great advances are being made in generating electricity from renewable energy sources the development of synthetic petrol is also vital, as electricity can currently only satisfy about 25% of our total global energy demand. “This is a very exciting step," said Professor Erwin Reisner. " Being able to produce syngas sustainably using sunlight would be a critical step in closing the global carbon cycle and establishing a sustainable chemical and fuel industry.”

The research was supported by Royce, the Maxwell Centre, and the University of Cambridge School of Technology, Yusuf Hamied Department of Chemistry, Department of Chemical Engineering and Biotechnology, and the Centre of Advanced Materials for Integrated Energy Systems (CAM-IES).

Project team members

Professor Erwin Reisner – Professor of Energy and Sustainability at the Yusuf Hamied Department of Chemistry;

Professor Sam Stranks – Professor of Optoelectronics and Royal Society University Research Fellow at the Department of Chemical Engineering and Biotechnology

Dr Virgil Andrei – Research Fellow at the Yusuf Hamied Department of Chemistry

Dr Miguel Anaya – Royal Academy of Engineering Fellow at the Department of Chemical Engineering and Biotechnology

Dr Motiar Rahaman – Marie Curie Fellow at the Yusuf Hamied Department of Chemistry

Yu-Hsien Chiang – PhD student at the Department of Physics

Dr Edoardo Ruggieri – Postdoctoral researcher at the Department of Chemical Engineering and Biotechnology

Related publications

Andrei V et al: 'Floating perovskite-BiVO4 devices for scalable solar fuel production.' Nature (2022), DOI: 10.1038/s41586-022-04978-6

Reuillard B and Reisner E: ‘Bias-free solar syngas production by integrating a molecular cobalt catalyst with perovskite-BiVO4 tandems.’ Nature Materials (2019). DOI: 10.1038/s41563-019-0501-6

Chiang Y-H et al: ‘Multisource Vacuum Deposition of Methylammonium-Free Perovskite Solar Cells’, ACS Energy Letters (2020), DOI: 10.1021/acsenergylett.0c00839

Macpherson S. et al: ‘Local nanoscale phase impurities are degradation sites in halide perovskites' Nature (2022), DOI: 10.1038/s41586-022-04872-1