At the outset, the process development that led to the current-day MCF process was a blue-sky research project with the aim of investigating novel techniques of creating controlled voidage in polymer extrudates. Today, however, a number of areas are being researched where MCFs are believed to be able to bring real advantages compared to current technology. Two key advantages that MCF extrusion has is that it is inherently low-cost in nature and that it is a continuous process, able to extrudate kilometre lengths of MCF during any given production run. Careful polymer selection coupled with this process can yield interesting systems many areas, for example use in flow chemistry, for plastic-based heat exchange and for fluid delivery systems.

|

Flow chemistry |

|

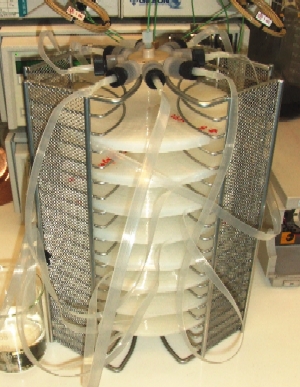

Heat exchange systems |

|

Dynamic pressure sensing |

|

Pumping and fluid delivery |