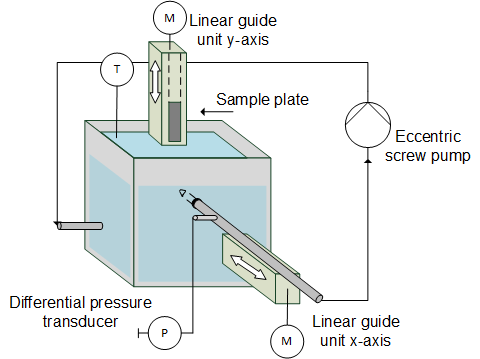

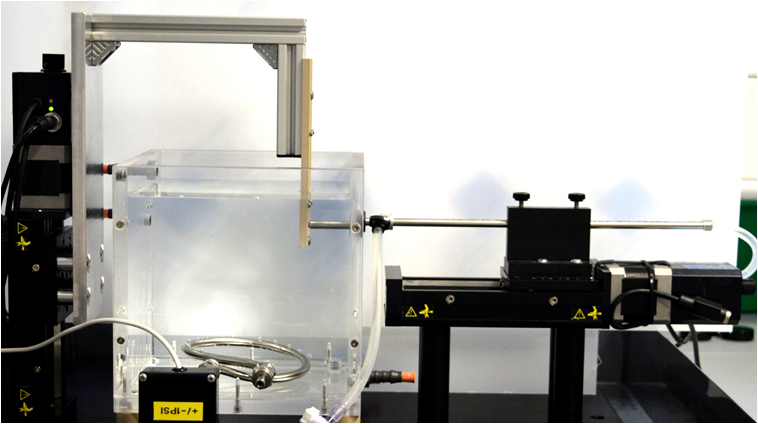

Some soft solid layers' properties change significantly on contact with liquid. However, it takes 1-2 minutes to mount a sample under standard FDG nozzles, so the initial behaviour cannot be accessed. The sideways FDG (SiDG) device was developed by employing a second linear slide as a conveyer to move the sample into the liquid environment, so the time between when the sample is first immersed and when the first reliable measurement is made can be minimised and the initial swelling can be monitored.

Related publication:

Tsai, J.-H., Cuckston, G.L., Hallmark, B. and Wilson, D.I. (2019) Fluid-dynamic gauging for studying the initial swelling of soft solid layers, AIChEJ, 69, e16664.

Continuously sideways FDG (cSiDG) (Lukas Schnöing, TU-BS)

A further development of the SiDG is the continuously operating variant (cSiDG). With the low-pulsation eccentric screw pump the measurement of the layer thickness and/or shear strength can be carried out without time interruption by changing from suction to ejection mode. The advantages of the conventional SiDG are of course retained.

Related publications:

Tsai, J.H., Cuckston, G.L., Schnöing, L., Augustin, W., Scholl, S., Hallmark, B. and Wilson, D.I. (2019) Fluid Dynamic Gauging for Studying Early Stages of Swelling of Fouling Deposits, Proc. 13th Intl. Conf. on Heat Exchanger Fouling and Cleaning, Warsaw, Poland.

Gottschalk, N.; Foisel, S.; Schlüter, F.; Augustin, W.; Scholl, S. (2017) Fluid Dynamic Gauging for Pulsed Flow Cleaning, Proc. 12th Intl. Conf. on Heat Exchanger Fouling and Cleaning, Madrid, Spain.