Fouling & Cleaning

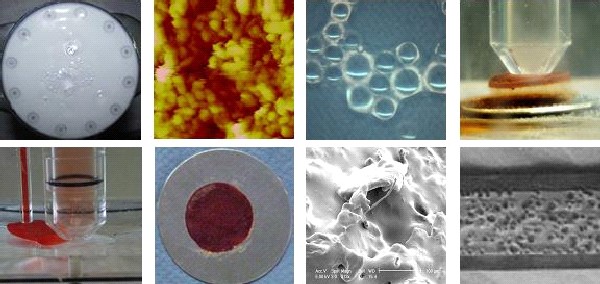

Biofilm (with Technical University of Braunschweig, Germany)

Unlike other types of fouling, the problems caused by biofouling are not limited only to reduced process efficiencies and increased operating costs. For instance, biofilms are not desirable in the food industry due to hygienic requirements, and the growth of biofouling may lead to corrosion. Cleaning of biofilms is not a straight-forward process mostly because of the adaptive ability of these films. Hence a series of cleaning studies of biofilms has been performed using FDG. This can be done in two modes: (i) obtaining thickness-time profiles of biofilms in various cleaning solutions at various conditions and (ii) estimating stresses needed to physically remove biofilms from various surfaces. It is hoped that FDG will give more insights into the cleaning of biofilms, which is a persistent problem in many industries.

Crude oil (with Imperial College and University of Bath)

Fouling in crude oil preheat trains is a significant industrial problem which has restricted the application of process integration techniques, such as pinch technology, in the oil industry. There are various substances that tend to deposit as fouling layers on the heat transfer equipment, the most common being asphaltenes. Deposition of asphaltene on the heat transfer surfaces reduces its thermal efficiency and can increase pressure drop. As the level of fouling increases, the thermal efficiency can be maintained an acceptable level only at the expense of higher operating costs. Direct measurement of the deposit thickness will provide information essential for improved scheduling of production, and cleaning protocols. This work is being performed as part of the large EPSRC-funded systematic study of crude oil preheat train fouling in collaboration with the University of Bath and Imperial College, London.

FDG is employed to continuously monitor the build-up of the fouling layer as it forms, in situ and in real time. The thickness information will allow optimisation of operating costs and development of maintenance strategy. This work involves the design, construction and operation of an annular test section in which fouling development will be monitored.

Food Fats & Whey Protein

Fouling and cleaning continue to play an important role in the food processing industry in terms of their influence on food safety and hygiene as well as on plant operability and production performance. There are never-ending regulations and commercial pressures for food hygiene standards to be stringent and yet cleaning is rarely given the attention it deserves. Cleaning problems are often complicated by variations in processing materials. Heterogeneous fouling layers present several challenges for analysis and monitoring. In particular, many food deposits, being foams, gels or high voidage structures, are readily compressed and may be difficult to study outside their native environment due to shrinkage or slump. Food fats (triplamitin) and whey protein gels/deposits are used as model food soils and FDG is being used to study their fouling and cleaning behaviours.

Membrane Fouling (with University of Bath)

Membrane technology is used in many processes, exploiting its high selectivity, and its ability to operate often without the need for additives and with relatively low cost and energy consumption. Most membrane processes suffer loss of performance over time due to the deposition of unwanted fouling layers upon, or within, the membrane, causing declining permeate flux, increased operational cost, and shortened membrane life. Fouling can occur from particles depositing on the membrane surface, macromolecules adsorbing onto the surface or into the bulk membrane material, or pore blocking. FDG is employed to study the deposition of solids behaviour on separation membranes. Part of this work is to combine optical microscopy with FDG to observe deposition of particles on membrane surfaces.

Polymer films (with NeoResins BV, NL)

Unwanted polymer layers depositing on reactor walls and impellers are frequently encountered in emulsion polymerisation processes. These unwanted surface layers can cause cross-contamination between batches, which is problematic when feedstocks are varied regularly. Regular cleaning is therefore necessary, and may employ chemical agents (e.g. soaking or spraying with solvents to soften and/or dissolve deposited material), hydraulic action (jets or sprays to shear material off) or a combination of both. The choice of chemical cleaning agent and operating methodology is often based on empirical testing. The removal of such coatings is often achieved by aggressive solvents which pose serious environmental impact. Hence there is a motivation of using alternative water-based formulations.

The work on polymer films focused on the use of FDG to track and thereby compare the cleaning characteristics of different solvents on a number of fouling layers generated by emulsion polymerization on laboratory test sections and in an industrial pilot plant. Also, we have investigated the effect of pH and ionic strength of salt-NaOH solutions on the swelling rate of the polymer layers.

CFD simulations

Quasi-stagnant

Computational Fluid Dynamics (CFD) studies have been performed to illuminate the fluid dynamics of FDG in the quasi-stagnant configuration, with particular focus on the flow patterns and on the stresses imposed on the surface. The governing Navier-Stokes equations were solved using the Augmented Lagrangian Method implemented by a commercial partial differential equation solver. The success of this CFD study will enable (i) use of the gauge to measure the strength of deposits, (ii) optimization of the shape of the nozzle for different tasks and (iii) extension of the technique to power-law fluids.

Duct-flow

Knowing how fluids will flow in an annulus and what will be the effects of the introduction of a fluid dynamic gauge, assists us in testing our designs before the rig is built, thus aiding us in consequent improvements. The results from the model can be compared with the literature and with our own experimental duct-flow data for accuracy.

The operation of FDG in turbulent flow conditions in an annulus is modelled using a commercial CFD package. The solution of the Navier-Stokes equation for steady state, incompressible, Newtonian fluid used a finite element technique. The information obtained from CFD simulations provides insights into the flow patterns and stresses involved in FDG operating in turbulent flow conditions.

Annular-flow

The only prerequisite for the FDG to work is that the foulant layer does not change shape while exposed to the forces imposed by the gauging liquid flow during the measurement. However, when the gauging flow does cause deformation, the mode and extent of this deformation can be exploited to estimate the strength of the layer by combining the observations with computational fluid dynamics (CFD) simulations of the shear and normal stresses acting on the foulant. CFD studies have been performed for cases where the bulk liquid (in the annular gap) being either stagnant, or in the laminar flow regime.

Strength Studies

The strength of the deposit, which is one of the key parameters in cleaning and removal, changes over time and is difficult to quantify. Quantitative links to cleaning performance parameters such as shear strength are rarely reported in the literature. Ageing usually results in stronger deposits as a result of extended reaction between organic components, diffusion to reduce deposit voidage or generation of adhesive extracellular material. Knowledge of the shear strength of these deposit layers would allow equipment designers to select flow conditions which would mitigate fouling by erosion of growing deposits.

Baked tomato paste

The mechanical behaviour of soft fouling layers is often overlooked, owing to the difficulty in quantifying this reliably, or is determined indirectly. Knowledge of the stresses imposed by the gauging flows on the surface would therefore afford a method for measuring the shearing yield strength of the deposit, as well as the deposit thickness, in situ and in real time.

CFD studies have been conducted to allow the stress field imposed on baked tomato paste by quasi-stagnant gauging flows, to be quantified. The velocity estimates calculated from the critical shear stresses required to fully remove the baked tomato paste are found to be higher than, but of the same order as, the lower limit of the range of velocities suggested for cleaning in place (CIP) installations. FDG is therefore capable of measuring both the thickness of deposit macro-layers and their mechanical properties in situ.

Crystal scales (with Technical University of Braunschweig, Germany)

The work on crystal scales is conducted in collaboration with the Institute for Chemical and Thermal Process Engineering (ICTV) at the Technical University of Braunschweig, German. This involved surface analysis and crystallisation experiments (ICTV's area of expertise), and the commissioning and testing of a new fluid dynamic gauging system at Braunschweig, and training ICTV workers in its use.

Surface interactions (with Technical University of Braunschweig, Germany)

Surface modification for mitigation of fouling, either by inhibiting attachment of depositing species or by increasing the ease with which they can be removed or cleaned, has attracted considerable attention in the food sector in recent times. Although various surface coatings are available and affordable, little is known regarding the effectiveness of these coatings. One of the reasons is because assessing the effectiveness of modified or structured surfaces requires information on deposit structure, strength and fouling or cleaning mechanisms, which is not readily obtained via pilot plant trails or simple test plates. A number of novel methods including FDG have been developed recently which afford direct measurement of fouling deposit strength characteristics under immersed conditions. Work has been done on assessing the strength of tomato paste deposit on a series of modified 316 stainless steels. Results obtained from FGD studies were related to surface properties characterized in terms of surface energy and surface roughness.

Polymer latex coatings

Drying of particulate dispersions is a crucial step in many manufacturing processes. This can be used to reduce transport costs so that the solid can be shipped alone, or for formation of a final product. Examples of high value products include colloidal crystals, whereas an everyday (and less expensive) example is a paint film.

When a dispersion of particles is dried to leave a solid behind, the film of material will develop mechanical properties. We intend to measure the development of film strengths directly using FDG. A well defined jet of liquid or air is made to flow over the the film and we can then determine the stress that causes the film to break. Initially silica particles that are about 20 nm in diameter will be used, and quartz substrates will be employed so that the film can be imaged from below.

Gelatine

Gelatine is one of the most widely used polymer in the food, pharmaceutical and bio sectors. Its physical properties, however, have not been thoroughly investigated. The investigation of the process for swelling of gelatine is important because swelling strongly affects the rheological behaviour of the gel. Gravimetric and FDG experiments have been performed to monitor the swelling behaviour (i.e. mass, yield strength and thickness evolution) in aqueous media.

Ageing (with Lukas Schnöing, Technical University of Braunschweig, Germany)

A substance tending to foul is transported to the wall and adheres. If the deposits are not removed by flow-induced shear forces, the high wall temperatures lead to material changes in the deposited substances over time. Such ageing processes cause changes in the morphology, which influence both the heat transfer and the strength of the entire layer and within the cross-section of the deposit. Alteration in strength can be expressed as mechanical ageing which is strongly dependent on the prevailing temperature in the deposit. Different methods are used including FDG to characterise cohesion and adhesion of whey protein deposits in terms of time and temperature dependent alterations of homogeneous model layers and heterogeneous real fouling layers. Results obtained can help to deepening the knowledge about optimal cleaning procedures.