Experimental study of soft layers on surfaces, in particular those involved in fouling and cleaning, often requires measurement of the evolving thickness of a soft deposit. In process equipment in the food and biotechnology industries, fouling deposits are often soft and fragile, and contain substantial fractions of liquid with consequent low rigidity. They are readily deformed by contact with any ordinary kind of stylus or probe, so that their thickness cannot be accurately measured with conventional mechanical instruments. Furthermore, the tendency of fouling deposits to shrink or slump outside their natural environment makes it difficult to gauge them satisfactorily in any other location. Thus, we need a technique or gauge that requires no physical contact with the deposit, is operable in situ and in real time, is capable of making local measurements and requires no assumption that the deposit is uniform in its properties.

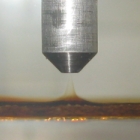

Fluid dynamic gauging (FDG) is a measurement technique developed in this group. It is based on simple fluid mechanics, and satisfies the requirements mentioned above. The application of FDG can also be extended by combining with other techniques. With computational fluid dynamics, FDG can be used to quantify the strength/deformability (rheology) of soft deposits. We have also coupled FDG with imaging technologies to look at the structure and behaviour of surface layers as they respond to the stresses that FDG imposes on them. The materials studied include whey protein gels, polymer latex, tomato paste, crystal scales and porous surfaces.

Fluid dynamic gauging (FDG) is a measurement technique developed in this group. It is based on simple fluid mechanics, and satisfies the requirements mentioned above. The application of FDG can also be extended by combining with other techniques. With computational fluid dynamics, FDG can be used to quantify the strength/deformability (rheology) of soft deposits. We have also coupled FDG with imaging technologies to look at the structure and behaviour of surface layers as they respond to the stresses that FDG imposes on them. The materials studied include whey protein gels, polymer latex, tomato paste, crystal scales and porous surfaces.

Fluid Dynamic Gauging Menu