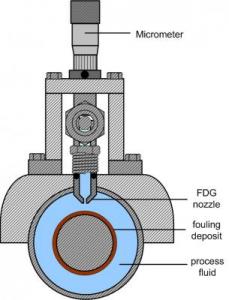

Recently, the FDG technique has been shown to operate reliably for a curved surface, where the gauging experiments were carried out on an annular geometry, with the bulk liquid being either stagnant, or in the laminar, transitional and turbulent flow regime. Annular configurations are often employed in fouling tests: the active surface is usually that of the inner cylinder, as the flow pattern is well understood and the fouling layer can be viewed in situ during deposition (for the case of a clear liquid and a transparent outer cylinder), and is readily accessible for analysis or inspection after testing.

|

|

The only prerequisite for the FDG to work is that the foulant layer does not change shape while exposed to the forces imposed by the gauging liquid flow during the measurement. However, when the gauging flow does cause deformation, the mode and extent of this deformation can be exploited to estimate the strength of the layer by combining the observations with computational fluid dynamics (CFD) simulations of the shear and normal stresses acting on the fouling deposit.

An example of the mesh of a CFD simulation (three dimensional) of an FDG in an annular flow system is shown below. The solution of the Navier-Stokes equation for steady state, incompressible, Newtonian fluid is evaluated using the finite element technique, COMSOL MULTIPHYSICS.