Introduction

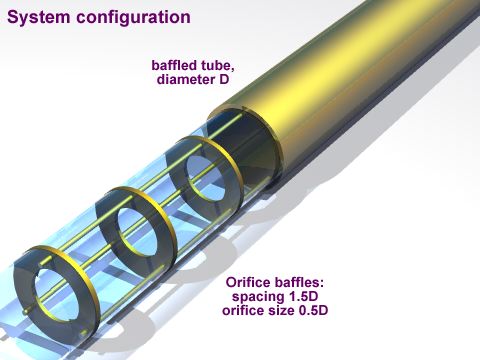

Good fluid mixing and efficient transport of mass and energy are key factors in many chemical and biochemical engineering operations. These conditions can be obtained by applying mechanical agitation in a vessel, or by operating in a high-velocity turbulent flow regime in a tube. An alternative method for achieving good mixing within a tube is by superimposing oscillatory flow on the steady flow in a tube with periodic, sharp-edged baffles (Figure 1). The method of mixing provides a range of specific process enhancements, such as improved mass transfer, heat transfer, and narrow residence time distribution (see Publications list).

|

|

Figure 1 - A 3-D schematic diagram of an oscillatory flow baffled tube. |

Key Advantages of OFM Technology

Oscillatory Flow Mixing can be applied to both batch and continuous processing, and it finds a wide range of applications in chemical, biochemical and process engineering.

The most outstanding features of OFM are:

- Significant enhancement of heat and mass transfer rates - enhancements are effective at low bulk flow rates (Re less than 300).

- Control of droplets/bubble size and size distribution.

- A platform for Process Intensification.

- Control of the Residence Time Distribution (RTD) - long residence times require only short tubes and a small L/d ratio.

- Suspension of particles.

- Fine-tuned mixing and shear rates - mixing is controlled entirely by the oscillations and not by the throughput.

For instance, the OFM allows designing a tubular reactor (Figure 2), which would offer the following advantages:

- plug flow RTD with high heat transfer

- finely controlled mixing

- homogeneous shear stress

- long reaction times

|

Figure 2 - Prototype tubular oscillatory flow reactor |

Our past and current research has been concentrated on understanding the science of OFM, using cutting-edge techniques and numerical simulation tools. We pioneer the Process Intensification of two-phase (immiscible liquid-liquid, gas-liquid and liquid-solid) and multiphase flow systems using oscillatory flow reactors towards the main goal of designing more sustainable industrial processes. We explore experimentally important aspects of reaction engineering in oscillatory flow reactors, especially residence time flow behaviour, scale-up and scale-down procedures, supported by CFD tools. OFM finds a broad number of industrial applications, including wastewater treatment, biofuels and fine chemicals production, and bioprocessing, with outstanding improvements in selectivity and quality for productions in the range of kilograms-per-day up to tons/hour (large-scale plants).

For more information select one of the following links:

- Advantages of OFM

- Process intensification

- Meso-reactor

- Numerical simulations

- Facilities

- Technology transfer

- Publications

- Links

Research Projects |

Group Information |