|

Oscillatory Flow Mixing (OFM) within a meso-reactor |

Good fluid mixing and efficient transport of mass and energy are key factors in many chemical engineering operations. These conditions can be obtained by applying mechanical agitation in a vessel, or by operating in a high-velocity turbulent flow regime in a tube. An alternative method for achieving good mixing within a tube is by superimposing oscillatory flow on the steady flow in a tube with Sharp Periodic Baffles. This type of reactor is termed SPB-OFR. The method of mixing provides a range of specific process enhancements, such as improved mass transfer, heat transfer, and narrow residence time distribution.

Instead of sharp edged baffles, a novel, oscillatory flow with Smooth Periodic Constrictions (SPC-OFR or Meso-OFR) has been developed for meso-scale (millilitre) application. The meso-OFR offers equally good mixing to the SPB-OFR design, and shows good performance in multiphase flow. Contrary to the SPB-OFR, the SPC-OFR requires no internal baffle support structure, and has more homogeneous shear rate, making it potentially suitable for small-scale multiphase applications such as screening reactions, precipitation and crystallisation.

|

| Schematic showing conventional Sharp Periodic Baffle Oscillatory Flow Reactor (SPB-OFR) |

|

|

Image of meso-scale Smooth Periodic Constriction Oscillatory Flow Reactor (SPC-OFR) developed in this project. These vessels, manufactured in glass, include circulation jackets to allow heating and cooling of meso-scale reactions. |

The fluid mechanics of a SPB-OFR

For steady flow in a smooth walled tube, the transition from a laminar Poiseuille flow to a turbulent flow happens at a relatively high Reynolds number (>4000). By altering the internal geometry to include periodically spaced baffles in the tube and superimposing fluidoscillations, the above transition occurs at a relatively low Reynolds number. The oscillating fluid motion interacts with each baffle to form two pairs of vortices in each inter-baffle cavity, providing efficient, uniform mixing throughout the length of the reactor.

|

| Experimental flow pattern at Re=200, St=1.0, obtained by Particle Imaging Velocimetry (PIV) |

A high precision numerical method for solving three-dimensional flows in a SPB-OFR has been developed by Dr Jie Li at the Cambridge University Engineering Department and BP Institute. The flow pattern is that pairs of toroidal eddies shed from the left-hand baffle will hit pairs of toroidal eddies generated from the right-hand at the flow reversal. The energy of the collision of these opposite eddies results in a breakdown in the flow symmetry at a small Reynolds number. Numerical observations show the development of asymmetric flow patterns at Re=300 within an axial section and a transverse section.

|

| Numerical flow pattern at Re=300, St=1.0 within an axial section. |

|

| Numerical flow pattern at Re=300, St=1.0 within a transverse section |

The fluid mechanics of a SPC-OFR

When oscillatory flow is applied in the meso-reactor, a single vortex pair forms downstream of the constrictions, and propagates in the cavity until the flow reverses. This is seen in the PIV animation below (left). The experimentally obtained values are compared with results obtained from three-dimensional numerical simulations using Fluent software (below right). In both cases, the flow Reynolds and Strouhal numbers were Re=312, and St=0.4. Clearly, the simulation provides a good prediction of the flow patterns for the oscillatory flow within a meso-reactor.

|

|

| Experimental PIV measurements | Numerical flow simulation |

Multiphase applications

Liquid-liquid mixing: The vortex mixing mechanism and the resulting high shear rate in the meso-reactor give good performance in liquid-liquid mixing (e.g. oil and water). Varying the oscillation frequency and amplitude can be used to control the droplet size, as seen below.

|

|

|

| Oil droplets formed by oscillations at frequency 6Hz and amplitude 2mm | Oil droplets formed by oscillations at frequency 6Hz and amplitude 3mm | Oil droplets formed by oscillations at frequency 10Hz and amplitude 2mm |

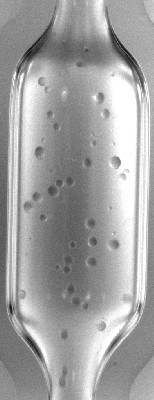

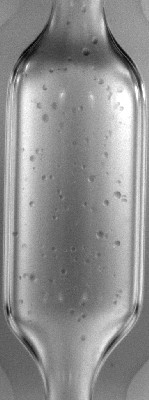

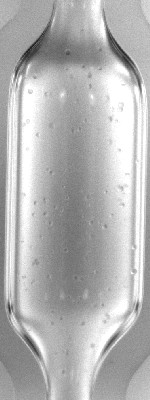

| Particles in suspension: Particles can be suspended e.g. in liquids in stirred vessels, turbulent pipe flow and fluidisation by using steady flow. Oscillatory flow in the SPC-OFR as well as in SPB-OFR can also be used for this purpose. The meso-reactor has the ability to keep 40 % (v/v) of silica resin particles completely suspended, as seen on the right. Particles are easier to suspend with a horizontal rather than vertical OFR tube orientation. |  |